Filters we offer:

Fiberglass Filter, MERV 3-4

The Glasfloss GDS disposable filter is constructed of a heavy-duty, one piece craftboard frame. All corners are closed and sealed. The fiberglass filter media is coated with a non-toxic, non-flammable, odor free adhesive. The fiberglass media is constructed in a progressively dense fashion from air entering to air leaving side. The fiberglass media has a skin backing on the air entering and the air leaving side. The media and reinforced strut retainers are glued and sealed inside a heavy-duty, craftboard frame. All filters are classified under U.L. std. 900.

Filter changes: Recommend changing the filter at least once per month.

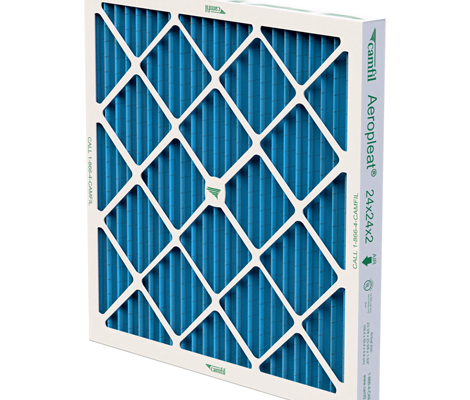

Standard Capacity Pleated Panel Filter, MERV 8

As a stand-alone filter, the Aeropleat III will remove many contaminants associated with today’s indoor air quality concerns. Available in 1”, 2” and 4” depths, its increased media area offers an extended service life when compared to lower efficiency throw-aways or pads. Applications include commercial buildings, educational facilities and specialty manufacturing. As a prefilter, the Aeropleat III offers protection for the higher efficiency final filters required for today’s high-technology applications. Built for today’s HVAC systems, the Aeropleat III compares to the filters you might see at a big box store. However, the Aeropleat III has some additional features to make it more appealing, longer lasting, and more effective than it’s similar competition.

- The Aeropleat III has 10 pleats per linear foot (2” deep model) with a radial pleat design for full use of media area

- A cotton and synthetic media blend which provides medium grade ASHRAE performance and high dust-holding capacity.

- Includes a welded wire media grid that is treated for corrosion resistance and prevents media oscillation or pull-away. The wire grid is manufactured from reclaimed metals in accordance with Camfil’s sustainable initiatives.

- Has a high wet-strength beverage board frame that is bonded to the media to prevent air bypass. Diagonal support members of the same construction are bonded to he media creating a rigid and durable filter pack. The filter will withstand 2.0” w.g. without failure.

Filter changes: Recommend changing the filter at least once per month.

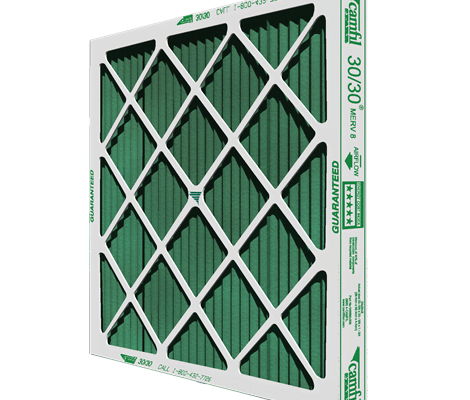

Upgraded High Capacity Pleated Panel Filter, MERV 8

Used as a stand alone or as a prefilter, the Farr 30/30, proven to be the industry’s best value for medium efficiency filtration, has an Energy Cost Index (ECI) of five stars—the highest performance rating available. The Farr 30/30 ® is an excellent choice when applied as the only filter in a system to keep coils clean, maintain efficiency, and protect building occupants from contaminants such as pollen, plant spores, atmospheric dusts and other indoor air irritants. The life of final filters if used, can be extended by capturing larger contaminants and allowing the final filter to concentrate on removing smaller particles.

Performing at MERV 8/8A and ePM10 under ASHRAE and ISO filter testing standards respectively, the Farr 30/30 media is manufactured from a proprietary blend of fibers that uses a mechanical particle capture principle, which does not require an electret charge. The electret charge of the competitors’ coarse fiber filters dissipates over time resulting an earlier high-pressure drop and loss of efficiency long before what should be a full life cycle. The Farr 30/30 is guaranteed to 2.0″ w.g. of pressure filter without failure. Costly filter blowouts and compromised cleanliness of HVAC systems is dramatically reduced if not eliminated.

The Farr 30/30 ® upgraded features

- High lofted media, it is twice as thick as similar filters. The media is lofted to a uniform depth to enhance the depth-loading characteristic and ensure the longest life of any pleated filter available. The high-loft also offers a lower resistance to airflow so fan horsepower required to move air through the filter is minimized.

- Radial pleats, this exclusive design feature allows the Farr 30/30® filter to expose all of the media to the dirty airstream which provides a lower pressure drop and higher dirt holding capacity.

- Welded wire grid provides complete media support and maintains pleat configuration as filter airflow resistance increases, this means it’s built to withstand the toughest airflow conditions

- The high wet-strength beverage frame and welded wire media backing provide structural integrity in any type of HVAC application virtually eliminating the additional costs associated with filter bypass or filter failure

- Every 30/30® filter is identified on the frame with a unique manufacturing code that allows us to analyze every component of construction from raw materials to the point where the product is boxed for shipping. Filters are inspected for structural integrity so they are capable of operating in the harshest HVAC system conditions. The adhesiveness of diagonal support members to pleat apexes is inspected so pleat spacing is uniform to provide longer filter life. Each media lot is laboratory tested to confirm consistent performance and individual filters are submitted from each manufacturing facility on a strict schedule for ASHRAE 52.2 testing in our world-class testing facility, this conforms to the ISO 9001:2015 certification for Quality Control.

- Energy Cost Index (ECI) of 5 Stars, ECI compares filters of similar construction, under the same conditions of operation and provides an indicator of TRUE performance. Specifically, the formula is dollars per percent of filter efficiency. The lower the value, the better the filter. A filter with an ECI of five stars is a stellar performer. It maintains its efficiency over its life and uses less energy to move air through the filter. It is in the top 20% of all filters evaluated. A four-star filter has a lower ECI value, and the pattern continues down to one star, the poorest performers.

- Guaranteed to perform at the rated efficiency, or better, throughout the life of the filter.

- We guarantee that Camfil 5-Star Premium Filters will substantially reduce HVAC-related energy consumption, require less frequent change-outs, and reduce waste and environmental impact. We’re the only air filtration company that guarantees our product performance. Look for the Camfil guarantee logo and 5-Star rating.

Filter changes: Recommend changing the filter at least once every other month.

Bryant ® EZ-Flex MERV 10 Media Air Cleaner

The Bryant EZ Flex is an excellent choice when applied as the only filter in a system to keep coils clean, maintain efficiency, and protect building occupants from contaminants. The life of final filters can be extended by capturing larger contaminants and allowing the final filter to concentrate on removing smaller particles.

The EZ Flex performs at MERV 10 under ASHRAE 52.2. It has low airflow resistance and does not produce a significant pressure drop. The high dust holding capacity allows for extended times between filter changes.

Filter changes: Recommend changing the filter at least twice per year.

Honeywell PopUP MERV 11 Media Air Cleaner.

The Honeywell Popup is an excellent choice when applied as the only filter in a system to keep coils clean, maintain efficiency, and protect building occupants from contaminants. The life of final filters can be extended by capturing larger contaminants and allowing the final filter to concentrate on removing smaller particles.

The Honeywell PopUP performs at MERV 11 under ASHRAE 52.2. It has low airflow resistance and does not produce a significant pressure drop. The high dust holding capacity allows for extended times between filter changes.

MERV 11 Honeywell Pop Up Filter fits other media air cleaner cabinets as well, such as Aprilaire, Bryant, and Carrier.

Honeywell Pop Up features

- No Assembly Required – No combs, pleat spacers or end caps. Filter simply pops up and is ready to use.

- Homeowner Friendly Self-Assembly – Open package and POP! The filter is ready to install.

- Collapsible Design – Less chance of damage and makes for easy, clean disposal.

- Meets American Lung Association Health House Guidelines – Fiberglass Free!

- Extra Filtration – the Pop-up design offers an additional 1 inch of depth compared to standard cartridge replacements

Filter Changes: Recommend changing the filter at least twice per year.

Electronic Air Filter, MERV 15

Bryant® Air Purifiers are great for homeowners with allergy concerns, individuals susceptible to airborne germs such as infants and the elderly, and those with sensitivity to the effects of pollen, pets and more. Compared to many portable air cleaners, the Evolution Air Purifier is silent and can treat 100% of the air flowing through your home comfort system. The patented Captures & Kills® technology provides a 99% inactivation rate against select viruses and bacteria.* No cleaning required. Simply remove and replace the filter cartridge periodically to maintain peak performance.

How do they work?

- Step 1: The Evolution Air Purifier uses precision point ionization to charge particles as they enter the purifier.

- Step 2: A specially designed, continuously charged media filter captures airborne particles.

- Step 3: Patented, state-of-the-art technology kills select captured viruses and bacteria* and can prevent further growth of organisms on the filter

Filter changes: Recommend changing the filter and cleaning the ionization array at least twice per year.

HEPA Filters

HEPA (High Efficiency Particulate Air) filters must be tested and must achieve removal of 99.97% of particles down to a submicron level in the air. There are filters designed to remove 99.9999% of particulars as well. HEPA filters are used in a mainly commercial setting. Healthcare facilities, educational facilities, industrial, museums, libraries, hotels, airports, and other commercial, industrial, and medical facilities are some examples of locations that might use HEPA filtration. They are generally not recommended in residential settings. A residential setting would have to have their system designed to be HEPA or a least a costly modification of their current system including the furnace and ductwork to accommodate a true HEPA filter installation. Beware any product claiming “True HEPA”, “HEPA-type”, “99% HEPA” as they do not meet the HEPA standard for testing.